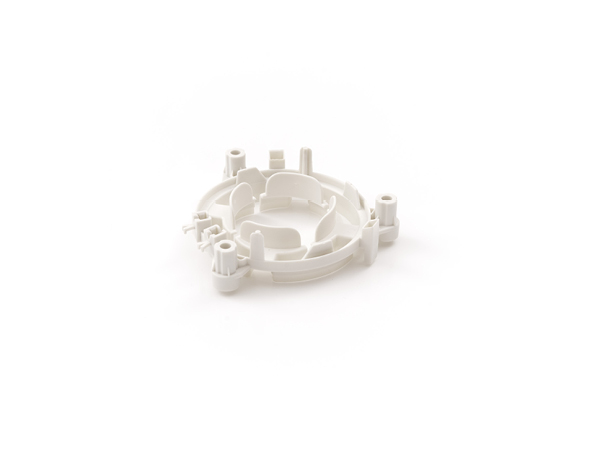

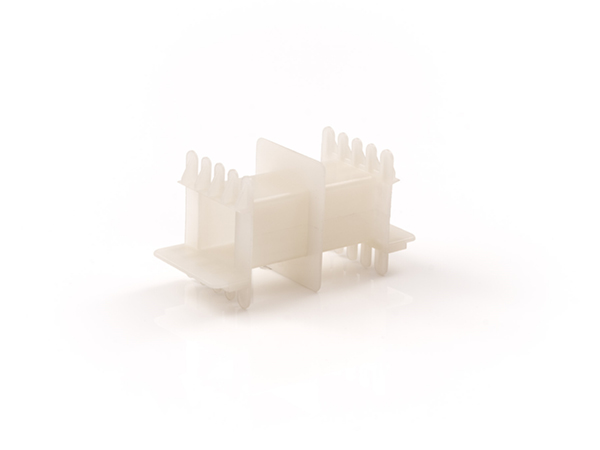

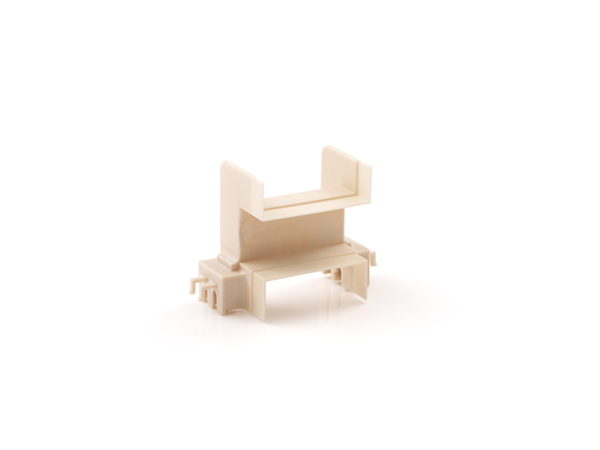

Coilers

Coils of various shapes are mostly made of thermoplastics such as PA6, PA66, PET and LCP. The materials must provide the product with adequate electro-insulating properties, temperature stability and fire resistance. Due to the geometry of thin walls, additives for thermal stability, self-ignition, etc., it is extremely important to control the process, which includes the correct preparation of the material, control of the melt temperature and the temperature field across the tool.

Additives, used for such products, degrade at inappropriate temperatures, which impairs the product's function. Our company has 50 years of experience in the development and injection molding of coils, which enables us to solve challenges more easily. Due to these types of products, we have been certified for production according to the UL standard for 25 years, which enables us to install our products all over the world.