Our services

Za zagotavljanje hitrosti, odzivnosti, natančnosti in kakovosti imamo v podjetju vpeljanih več različnih procesov. Najbolj osnovna sta procesa brizganja plastičnih mas ter proces kontrole. Podporo osnovnim procesom predstavljajo razvoj orodij, tehnologije in avtomatizacije ter izdelava orodij.

Z razvojem avtomatizacije izboljšujemo učinkovitost in ponovljivost procesov, z razvojem lastne orodjarne pa povečujemo fleksibilnost ter hitrejšo odzivnosti v podporo proizvodnji.

Development of plastic injection

molding tools

A well-made tool is the first condition for a quality product. With more than 50 years of experience, we know the tool manufacturing processes and experts in our market. We make the necessary tools ourselves or in cooperation with specialists for the production of thermoplastic injection molding tools. Tools are designed and manufactured based on item specification. Tool production is completed with sample pieces, production documentation and customer approval.

We specialize in the development of tools for smaller products made of technical thermoplastics. For this purpose, we standardly equip the tools with the necessary components that enable control, safety and repeatability of the process. Standardizing tools allows us to use them on different production units. Only this gives our customers additional assurance of the feasibility of production and on-time deliveries.

When designing the tool, we take into account the expected quantities and the lifetime of the tools. Our goal is to produce a robust tool that requires minimal maintenance during its lifetime. For this purpose, we use only quality materials and built-in elements.

Injection

molding of plastics

Injection molding machines in a modern production area are managed by a team of qualified employees in three shifts. We have about 18 injection molding machines available with a closing force of 28t-220t.

More and more machines are equipped with Cartesian robots, which serve for controlled removal of products from the machine and subsequent processing of the product in automated cells. Most of our production is equipped with Engel tie-bar-less machines, which have been synonym for quality for decades.

To ensure quality material preparation, each machine is equipped with its own drying system. The machines are also equipped with sensors to control the temperature of the tools, hot runner systems and technological water.

We use a central vacuum system to transport the granulate, which prevents the blowing of dust and impurities into production area.

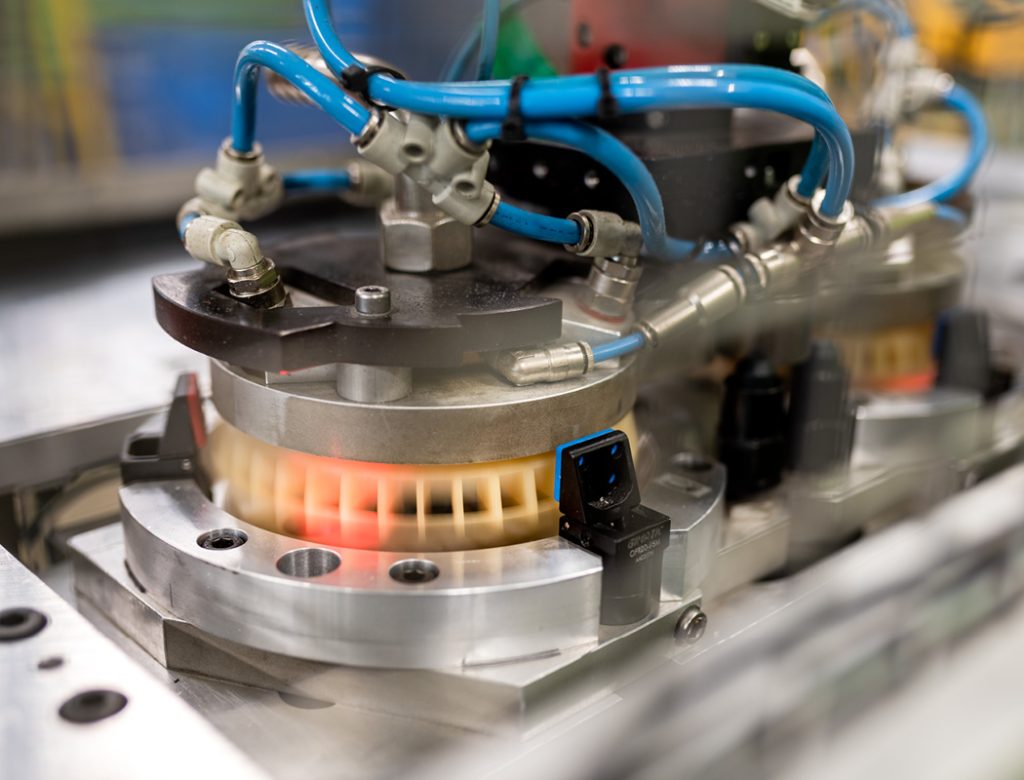

Automatization of product

post-processing

Post-processing of the product can include removal of the filler clip, burrs, etc…, measuring the part, installing inserts or printing. The initial steps of automation were carried out in cooperation with established experts for the manufacture of automated cells. Recently, based on the experience we have gained, we also carry out both maintenance and development of new cells ourselves. Integrated Cartesian robots allow us to develop the automated post-processing of the article relatively quickly, even for smaller batches.

More demanding processing is based on independent cells, equipped with universal multi-axis robots or with dedicated drives for manipulation, processing and measurement.

The introduction of automation in the company brings shorter work cycles and greater process repeatability. Both for us and for our cooperators, the latter represent an advantage over competitors, as the products are of higher quality and more economically advantageous.

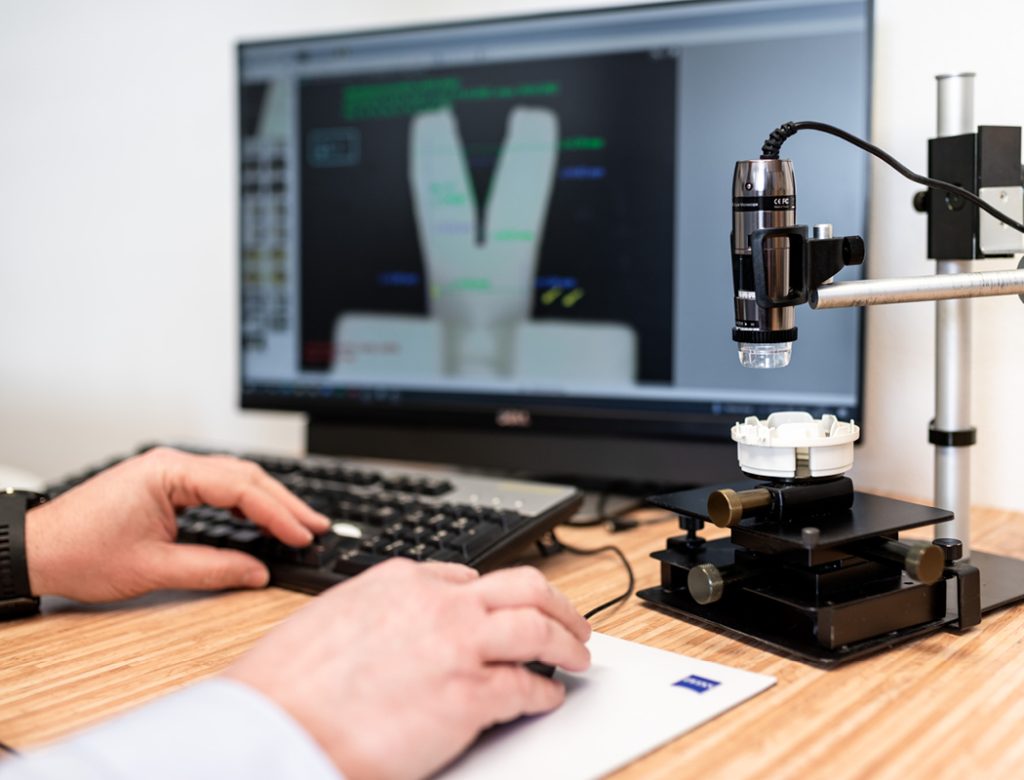

Product control

and quality assurance

Product control is integrated into the production process itself. Multi-level control includes control of production preparation, control of process parameters, control of products directly in production and parallel control by the quality department.

For the products in our production, we keep records of measurements, which enable us to track the characteristics of the products throughout the tool’s lifetime. By reviewing the records, we can identify process trends and react in time to prevent process and product inconsistencies.

For the needs of process and product control, we have at our disposal a coordinate measuring machine, a balancing machine, an optical and two-coordinate microscope, dynamometers, a thermal camera and other special equipment.

The company has been certified according to the UL Underwriters Laboratory standard since 1999, and since 2007 according to the ISO9001 standard.